- Up to 8–16 panels/min

- 800 kg lead furnace

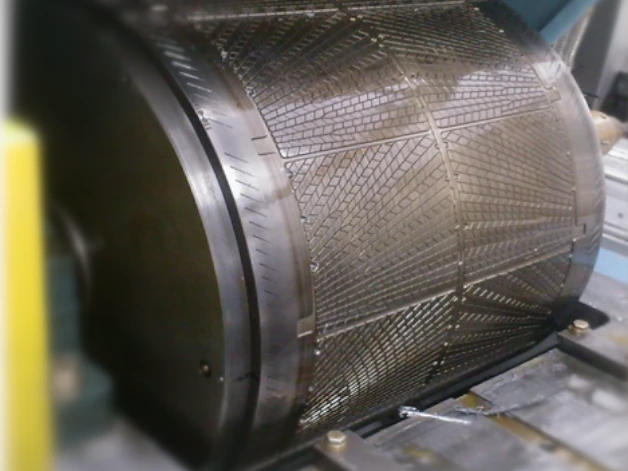

Battery plates

7500–15000 pcs

Last updated on September 1, 2024

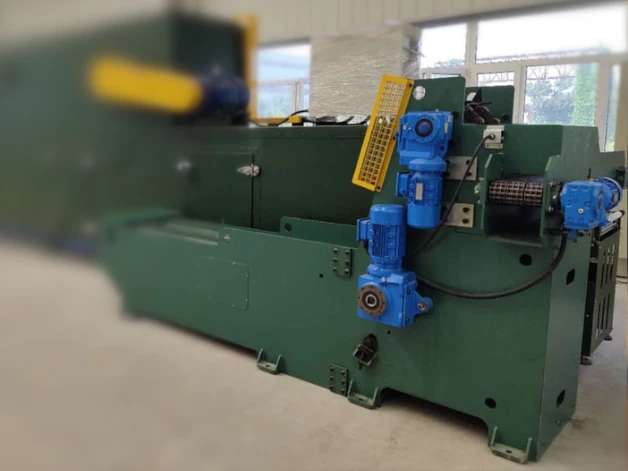

Curing is one of the most critical steps in lead-acid battery plate production, and can be decisive for the quality of the plates and the battery’s capacity and life cycle. The right choice of curing chamber will affect the quality of the active mass and determine the microstructure of the lead crystals, which play a central role in battery formation.

In order to achieve the desired quality, it is necessary to keep certain parameters, including free lead content and residual humidity under control, which can be a haunting task depending on the chamber design. An additional difficulty results from the typically long cycles of the curing process.

An efficient process can significantly reduce the overall production time and costs. Our chambers are made of robust materials and can handle any type of grid, regardless of the oxide paste and grid production method (casting, continuous casting, punching, etc.). We offer many configuration options, including the heat source (electric or gas) and size.

A PLC is used to control and monitor each step and ensure uniform temperature, humidity, and an air flow throughout the entire cycle. All settings are easily accessible on a user-friendly HMI.