- Up to 4 pcs/min (car)

- VFD controlled vacuum

Lead-acid batteries

Up to 6 pcs/min

Last updated on August 30, 2024

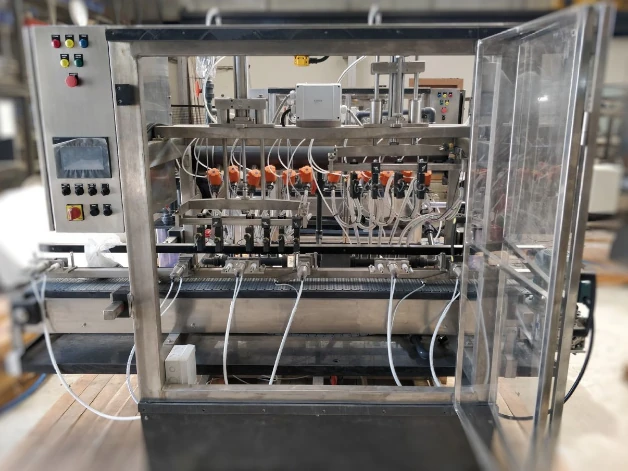

Available in five different technologies (sensor-controlled, volumetric filling with individual or combined flow meters, volumetric filling with floats or pressurized unloading with variable time), our line of acid filling solutions can meet every battery makers’ demands in terms of both precision and production capacity.

All structural components are made of SUS 316L stainless steel — the gold standard for any work this kind of application — with an additional layer of acid proof paint. Other components use corrosion resistant materials like ultra-high molecular weight polyethylene (UHMWPE), PVC or Teflon.

| Sensor controlled | Individual cell volumetric | Combined volumetric | Volumetric with floats | Pressured unloading | |

|---|---|---|---|---|---|

| Capacity | 3 pcs/min | 4 pcs/min | 4 pcs/min | 6 pcs/min | 6 pcs/min |

| Remarks | Filling and suction | Individual flow meters for each cell | Single flow meter for the entire battery | With variable time |

(The above estimate assumes a 18 l volume)