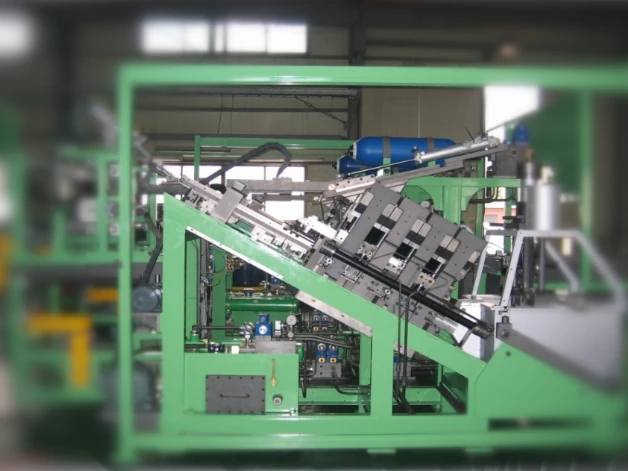

Our fully auto. intercell welding machines use an exclusive, patented technology, with a 2-way servo that allows for a more granular control of the pressure and other welding parameters, ensuring that the contact surface is the same every time. It is also easier to configure and set up than more traditional alternatives.

Thanks to a clever, modular design, several tests can be integrated into this machine, including the pre-welding short circuit test and the post-welding short circuit and internal resistance tests (also known as weld quality inspection), saving valuable space on the factory floor.